While the process can take hours in some industries for certain applications, effective sterilization in others can be performed relatively quickly. The biggest advantage of the gamma sterilization process is that when it's used correctly, it's both efficient and effective. This makes it relatively easy to learn and execute. In fact, only the sterilization dose or "radiation dose" and exposure time are required to be monitored by those who oversee the gamma sterilization process. This sterilization method is fairly easy to administer. It offers better (deeper) penetration, a higher certainty of sterility, and its effectiveness is independent of temperature and pressure conditions.

Gamma radiation has several advantages over other sterilization methods.

#Disadvantages of using cobalt 60 iso#

In fact, it's backed by ISO 11137, the internationally recognized standard to achieve a defined sterility assurance level or SAL.

When administered correctly, gamma sterilization is safe and effective. Gamma Radiation Sterilization Advantages and Disadvantages Advantages of Gamma Radiation Sterilization Aside from use in the medical industry, gamma sterilization also proves beneficial when working with: The method can also sterilize personal protective equipment (PPE) both before and after use, so it can be used again. This is why medical tools are required to be properly sterilized prior to use.

#Disadvantages of using cobalt 60 free#

"Sterile" by medical terms, is defined as free from bacteria or other microorganisms to the point where they cannot reproduce and create any further contamination.Īs you might expect, performing surgery or a procedure on a patient with contaminated medical tools has the potential to lead to infection or further complications. The gamma sterilization process is commonly used in the medical industry to disinfect certain tools and products (i.e., implantable medical devices, surgical gowns, etc.).

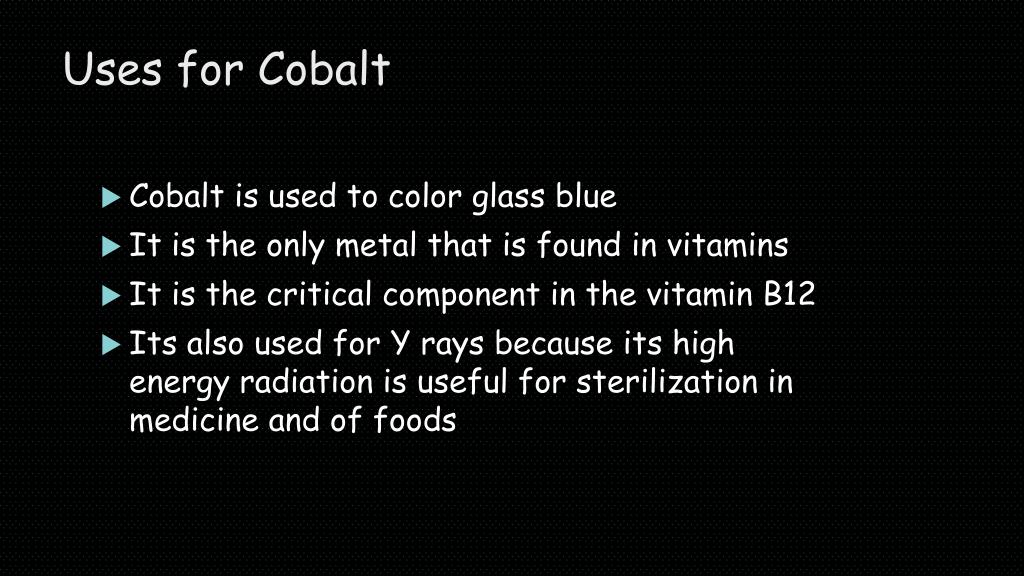

What Industries Use Gamma Radiation Sterilization? It's often used to treat groups of products/items on an as-needed basis. The batch process works a little differently, commonly consisting of loading one or more totes into a radiation chamber for treatment. This process is commonly utilized on large sums of products at a time. In a continuous format, item(s) pass through an automatic conveyor system where they're exposed to radiation- in this case, gamma rays. The process has been in effect since the 1950s and is commonly carried out in continuous or batch formats. Essentially, the process works to alter a microorganism’s DNA so that it's destroyed and unable to multiply. Ionization causes disruptions to any cellular structure that it comes into contact with, destroying organisms at the molecular level and making it impossible for them to reproduce. Powered by Cobalt-60, the low-dose process is administered when high-energy photons are emitted from a radiation source, which works to ionize the product or item in question. Gamma Radiation Sterilization ExplainedĪs the name implies, this is a sterilization process, and it's commonly used to kill bacteria and microorganisms that may be living on the surface of products, packaging, or goods. It can also be used to sterilize personal protection equipment (PPE) for reuse by professionals throughout a variety of industries. Though it’s most commonly associated with the medical industry, it's also used in fighting infestations in agricultural products, on product packaging, for reducing microbial contamination on certain foods, and more. The most popular form of radiation sterilization, gamma radiation sterilization, is a process used throughout many industries. Gamma Radiation Sterilization: A Key Weapon in Bacteria & Microorganism Elimination

0 kommentar(er)

0 kommentar(er)